Capabilities

MITTERNIGHT BOILERWORKS

Mitternight Boilerworks Priorities

Commitment to Safety

No job is so urgent that we cannot take time to perform it safely

Commitment to quality

Dedication to quality is the only way to ensure customer satisfaction time after time

Commitment to Courtesy

Exhibiting a cooperative spirit of politeness and courtesy

Sectors and processes:

- Crude

- Sulfur

- Coker

- Acid/all

- Steam

- Hydrogen

- Nasa

- Nuclear & Security

- Pharmaceuticals

- Food/Beverage

- Cryogenics

- Biofuels

- Government Agencies

- Parolysis

- Electrolysis

- And others

Mitternight Boilerworks Quality

Committed to Highest Standards of Quality

- Experienced staff (combined 85 years of experience among QC Leadership

- Influencers and thought leaders with multiple contributions to existing code Section VIII Div. 1 regulatory body

ASME Code Shop

- U, U2, S, R, Chinese Stamp, PED

Field Work is ASME, API, and AWS Certified

Quality Manual and NDE Standards apply to all Divisions of Mitternight Industries

Engineering

Full Service Design, Engineering, Fabrication and Installation

- Create the Design and Perform Calculations in accordance with ASME Code and Regulations

- Utilize Software Suites including Compress, AutoCad, and SolidWorks

- Provide Value Engineering for your product ensuring the best for your business

- Prepare pressure vessel datasheets and P&ID

- Process design including HTRI.

- Professional Engineer on staff

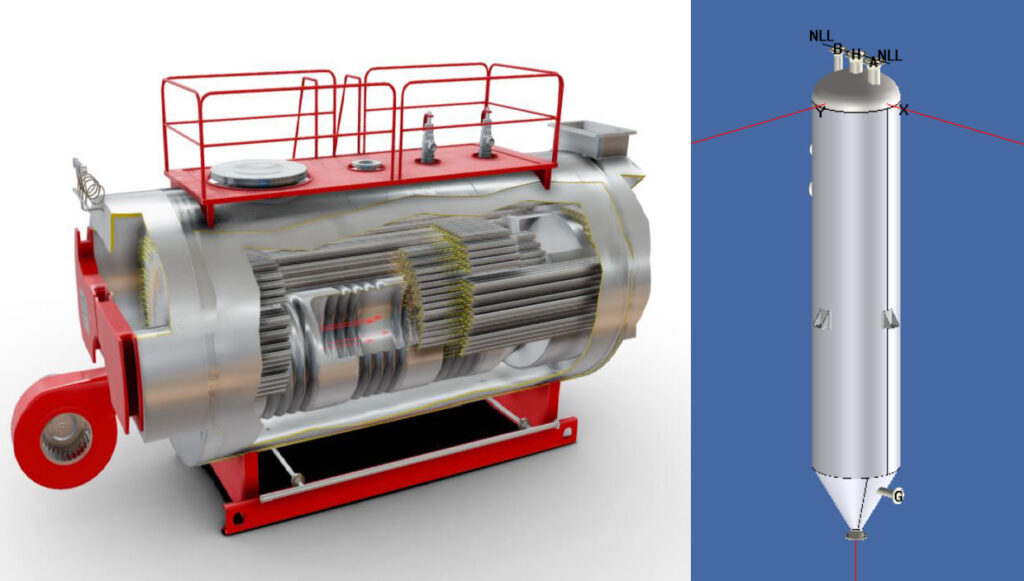

ENGINEERING & MODELING

Pressure VesselS

- ASME Section VIII Section VIII Division I and II

- All high nickel alloys including C2000, C22, C276, AL6XN, Alloy 20, 600, 625, 800 and 825

- All duplex stainless steels as well as conventional stainless steel

- Standard Carbon Steel

- Titanium

- Monel

- APMT

- Zirconium

CHEMICAL REACTORS

- External and Internal Coils

- Half pipe jackets

- Dimple Jackets

TOWERS & COLUMNS

- Dehydration Columns

- Distillation Columns

- Scrubbers

- Static Mixers

- Autoclaves

BOILERS

- RWGS

- Process

- Waste Heat Recovery

- Package Boilers

HEAT EXCHANGERS & TUBULAR REACTORS

- Hairpin

- U-bends

- Fixed and Floating Heads

- All TEMA Types

- Tubular Reformers

- Steam Methane Reformers

FIN FANS

- Air Cold Exchangers

- Engineering Design

- Manufacturing

Structural Steel

- Pipe Supports

- Ladders & Platforms

- Beams & Columns

THERMAL SPRAY

We offer a wide range of metalizing options including Zinc, Inconel, and Hastelloy

Industrial COatings & LININGS

- Piping, Tanks, & Vessels

- Industrial Coatings (All Types)

- Fireproffing

- FRP & Composite Linings

- NACE Certified Staff

- Glass & Rubber Linings

- Hard Surfacing (Stellite and Commodore)

Combustion Engineering and Fabrication

Full Service Design, Engineering, Fabrication and Installation

- 40+ years experience

- Leader since 1980 in Low Nox , Sox and CO2 Burners and Equipment Designs

- Installed equipment world wide

Combustion and Heat Transfer Equipment and Facilities

- Flares

- Furnaces

- Reformers

- Boilers

- Burner Management Systems

pipE SPOOL

Mitternight recently acquired a dedicated pipe fabrication facility.

- Mitternight currently operates this facility solely for the purpose of fabrication of pipe spools

- 10-acre facility equipped with blast and paint/coating capabilities on site

- Large lay down yard

- Ability to segregate material to maintain anti- contamination standards

- Operates under process piping codes B31.1, B31.3, and Mitternight ASME certifications.

Conveniently located approx. 5 miles from our fabrication facility in Mobile, AL

Non-Destructive Testing Division

Internal Testing Abilities:

- Radiography 2 Level II RT Inspectors, 1 Level I RT Inspector, 4 Level II RT (Interpretation Only

- Ultrasonic Testing 2 Level II UT Inspectors

- Magnetic Particle 3 Level II MT Inspectors

- Liquid Penetrant Testing 7 Level II PT Inspectors

- Visual Testing 5 Level II VT Inspectors

- Level 1 Nace Certified Inspector

- Hydrostatic Testing

- Pneumatic Testing

- Positive Material Identification 4 Certified PMI Operators

- Helium Testing

- Hardness Testing

- Ferrite Testing

- Ferroxyl Testing

Composite & Plastics DIvision

AL-FLA Plastics boasts a team of professionals on the leading edge of the composite and plastics industry

Design/Engineer/Build Capabilities

Applications include:

- FRP Lining, Tanks and support structure

- Dual Laminate piping

- HDPE and LDPE lining and welding

- UHMW

- Security/Protective Workplace Dividers

Field capability

- Ability to perform field services (New Construction and Repairs)

- Site installations

Workable units

- Crude

- Sulfur

- Coker

- Acid/All

- Steam

- Hydrogen

- (All Units)

THE MITTERNIGHT DIFFERENCE